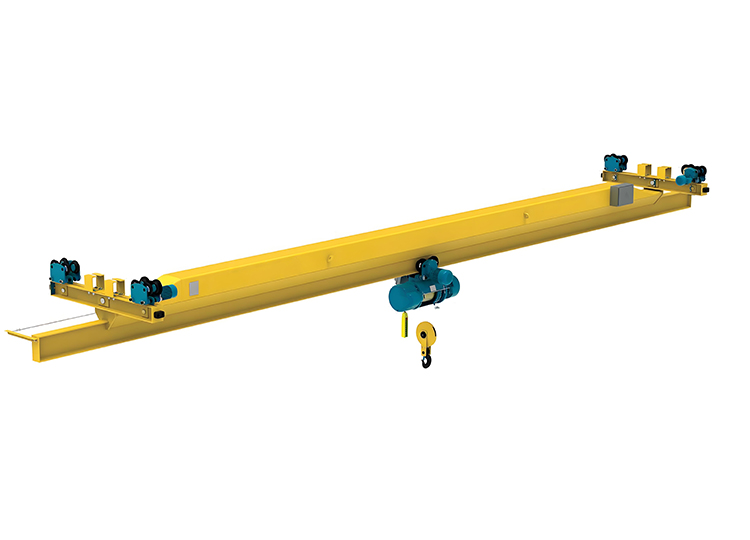

Suspension Overhead Crane LX Type

Mode LX type

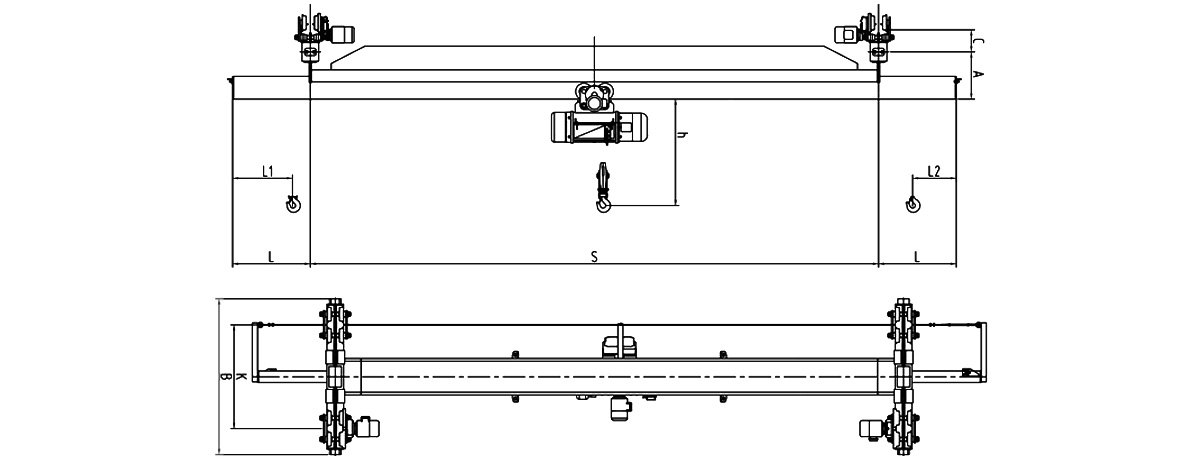

Span 0.5-10 meter

Lifting height 3-22.5 meter

| Terms | Unit | Magnitude |

| Loading capacity | ton | 0.5~10 |

| Span | meter | 3~22.5 |

| Crane traveling speed | m/min | 20m/min |

| Lifting speed | m/min | 7~8, 0.7~0.8/7~8 |

| Trolley traversing speed | m/min | 20m/min |

| Working Grade | -- | A3 |

| Power supply | -- | 3ph, 380V, 50Hz or customize |

LX single girder suspension overhead crane is specially for light-duty lifting scenarios, no more than 10 ton. Ceiling rails feature a larger effective span, and less deadweight compared with traditional overhead cranes. With CD1 or MD1 electric hoist, LX suspension crane shows incredible durability. Electric hoist consists of the motor, reducer, reel and wire rope. Its suspension device is a key component connecting main beam to factory or bracket, usually consisting of a boom, a connecting plate and a bolt. Some suspension devices are adjustable, which can adjust the height of the main beam according to the installation environment.

To bring long-term benefits, the main beam of suspension overhead crane is composed of I-beam and box beam. It generally connects with the factory or bracket through suspension devices. That makes it suitable for places with limited space, such as workshops, warehouses, etc. Its single beam structure makes the overall equipment lighter and more convenient to install and maintain. This structure makes it an ideal solution for low-clearance workshops with light-duty operation.

Application

Machinery manufacturing industryFor parts handling and assembly, which can effectively improve production efficiency and reduce the labor intensity of manual handling.Warehousing and logistics industryLoading, unloading, stacking and handling of goods, especially suitable for the handling needs of light and small goods.Food Processing IndustryHandling of raw materials and packaging of finished products. Their pollution-free and flexible operation characteristics meet the hygiene requirements of the food industry.Assembly workshop and laboratoryIn assembly workshops and central laboratories, it is for precisely positioned material handling and component assembly to meet refined operation needs during the production process.

Inquiry

Please leave us your requirements, we will contact you soon.